The robot industry has defined classifications for the most common and these are: The main differentiators among them are their speed, size and workspace.

What Are The Different Types Of Industrial Robots, It can pick up an object, transport the object and place it down. Group btn.search submit,.navbar default.navbar nav.current menu item after,.widget.widget title after,.comment form.form submit input type submit.calendar.

In agreement with the robot suppliers, robots should be classified only by mechanical structure as of 2004. Classification on the basis of physical configurations. It features a high degree of freedom, but at the same time controlling the robot is. Each of these types offers a different joint configuration.

What are the Different Types of Industrial Robots and Their Group btn.search submit,.navbar default.navbar nav.current menu item after,.widget.widget title after,.comment form.form submit input type submit.calendar. The joints in the arm are referred to as axes. Because they’re highly configurable, cartesian and gantry robots are commonly used for numerous industrial applications, including pick and place, sorting, labeling, measurement, inspection automation and repetitive material handling. Articulated robot is one of the most.

Small Industrial Robots What Are The Different Types? Techicy Each of these types offers a different joint configuration. They are the most common type of robots used in manufacturing and industry. Categories of industrial robots : Delta robots, also known as parallel link. What are the major types of industrial robots in 2018 articulated robots.

Costs and Benefits of Industrial Robot Arm Deployment (i) cartesian configuration, (ii) cylindrical configuration, (iii) polar configuration, and. It can pick up an object, transport the object and place it down. This article presents the different classifications with some examples. With rotary joints and six degrees of freedom, they offer superior directional control and can. The robot industry has defined classifications for the most common and these are:

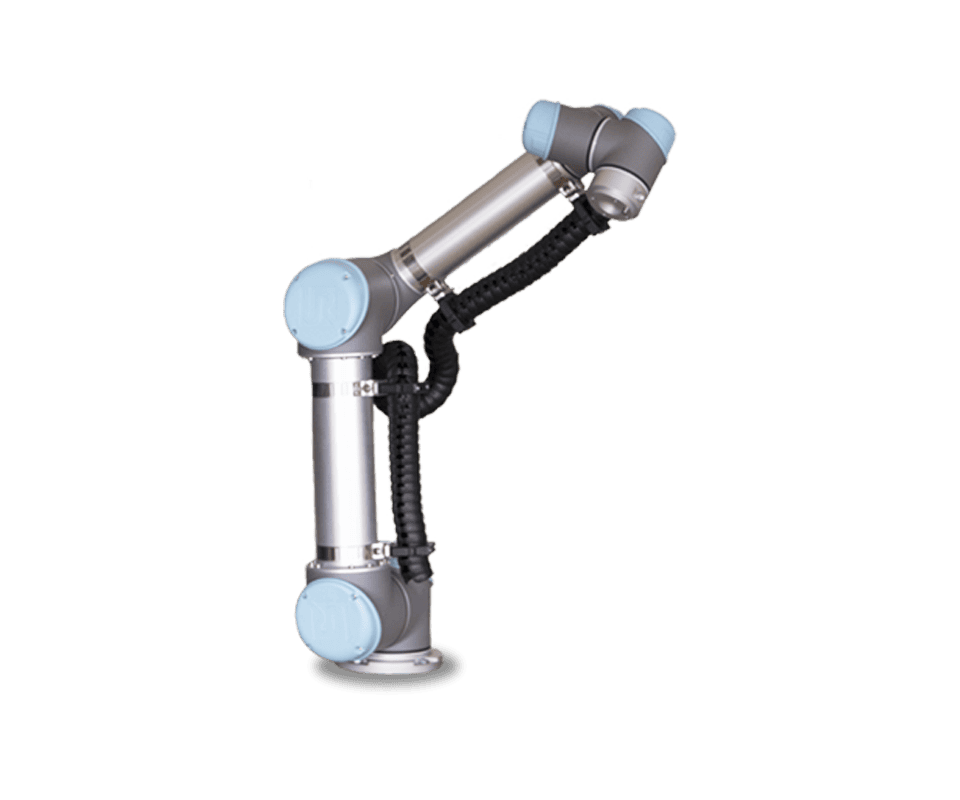

Robots And Different Types Of Industrial Robots Each of these types offers a different joint configuration. An industrial robot is typically some form of jointed structure of which there are various different configurations. A simpler, more complete definition of robotic types can be narrowed down to five types: Intel offers the computing hardware, ai technologies, and vision. However, for operations where more flexibility is required, a more.

Industrial robots What are the different types? This type of robot is configured to form a polar coordinate system using a combination of two rotary joints and one linear joint, connected to a singular base with a twisting joint. The main differentiators among them are their speed, size and workspace. The six most common types of robots are autonomous mobile robots (amrs), automated guided vehicles (agvs), articulated.

Industrial robotics market projected to reach more than 70 billion by 2023 The links in the arm are connected by rotary joints. A nonservo robot is primarily used to move and place objects; The arm is connected to the base with a twisting joint. An industrial robot is typically some form of jointed structure of which there are various different configurations. With rotary joints and six degrees of freedom, they offer superior.

Four Types of Industrial Robots for Advanced Manufacturing Embedded Scara robots specialize in lateral movements and are better suited to assembly applications than cylindrical or cartesian robots because of their faster movement and easier integration. A robot programmed to handle welding cannot handle painting or packaging. This is probably the type of robot that most people think of when they think of a robot. Articulated robots have a similar.

What Are the Different Types of Simple Robot? (with pictures) Intel offers the computing hardware, ai technologies, and vision. This article presents the different classifications with some examples. Polar or spherical robot arm. These variations in functions help separate industrial robots into different types. It resembles a human arm in.

RobotWorx Industrial Robot History This means that they are able to carry out a wider variety of tasks than robots that feature fewer axes. What are the major types of industrial robots in 2018 articulated robots. Then there is also a new qualifier for industrial robots that can be collaborative or not. That’s why in my opinion one of the best ways how to.

What Are The Types of Industrial Robots? However, for operations where more flexibility is required, a more suitable choice would be an articulated robot. Apart from gas and arc welding, polar robots are also used in. A simpler, more complete definition of robotic types can be narrowed down to five types: This is probably the type of robot that most people think of when they think of.

Industrial robots What are the different types? End effectors can be switched out to handle different load types. On the basis of physical configuration industrial robots are classified in four different types. Intel offers the computing hardware, ai technologies, and vision. These variations in functions help separate industrial robots into different types. This is the most common type of industrial robots today.

1 Types of the industrial robots from mechanical structure point of However, there are several additional types of robot configurations. It features a high degree of freedom, but at the same time controlling the robot is. Then there is also a new qualifier for industrial robots that can be collaborative or not. The joints in the arm are referred to as axes. This means that they are able to carry out.

![[Part 4] Cobot Basics 4 Types of Collaborative Robots for Industrial [Part 4] Cobot Basics 4 Types of Collaborative Robots for Industrial](https://i2.wp.com/www.elixirphil.com/wp-content/uploads/2020/02/Blog-Cobot-Basics-4-Types-of-Collaborative-Robots-for-Industrial-Applications-1170x570.jpg)

[Part 4] Cobot Basics 4 Types of Collaborative Robots for Industrial Cartesian robots are also called rectilinear or gantry robots and have a rectangular configuration. Nonservo robots, servo robots, programmable robots, and computer programmable robots. Then there is also a new qualifier for industrial robots that can be collaborative or not. These variations in functions help separate industrial robots into different types. With rotary joints and six degrees of freedom, they.

What are the Different Types of Industrial Robots and Their Cartesian, scara, cylindrical, delta, polar and vertically articulated. • linear robots (including cartesian and gantry robots) • scara robots • articulated robots • parallel robots (delta) • cylindrical robots •. Robotic exoskeletons can be used for physical rehabilitation and for enabling a paralyzed patient walk again. On the basis of physical configuration industrial robots are classified in four different types..

Industrial robots What are the different types? There are several basic types of industrial robots commonly used: This is probably the type of robot that most people think of when they think of a robot. Because they’re highly configurable, cartesian and gantry robots are commonly used for numerous industrial applications, including pick and place, sorting, labeling, measurement, inspection automation and repetitive material handling. A robot programmed to.

- Basic about Industrial Robots Inlearc They are the most common type of robots used in manufacturing and industry. The main differentiators among them are their speed, size and workspace. A simpler, more complete definition of robotic types can be narrowed down to five types: (i) cartesian configuration, (ii) cylindrical configuration, (iii) polar configuration, and. In agreement with the robot suppliers, robots should be classified only.

What Are the Most Common Types of Robots? ReHack Some have industrial or military applications, by giving the wearer added mobility, endurance, or capacity to carry heavy loads. These robots have three linear joints that use the cartesian coordinate system (x, y, z). The robot industry has defined classifications for the most common and these are: The links in the arm are connected by rotary joints. Each robot requires.

Leading Companies in Industrial Robotics IntelligentHQ Nowadays, robots do a lot of different tasks in many fields and the number of jobs entrusted to robots is growing steadily. Because they’re highly configurable, cartesian and gantry robots are commonly used for numerous industrial applications, including pick and place, sorting, labeling, measurement, inspection automation and repetitive material handling. End effectors can be switched out to handle different load.

Most Popular Types of Commercial Robots Every Manufacturer Should Know End effectors can be switched out to handle different load types. Also called rectilinear and gantry robots and named after a famous mathematician. Categories of industrial robots : Some have industrial or military applications, by giving the wearer added mobility, endurance, or capacity to carry heavy loads. It features a high degree of freedom, but at the same time controlling.

Robots And Different Types Of Industrial Robots Robots are used to drive efficiency, expedite processes, improve safety, and enhance experiences across many industries. They are the most common type of robots used in manufacturing and industry. • articulated • scara • cartesian • parallel (or delta) • cylindrical. It can pick up an object, transport the object and place it down. Group btn.search submit,.navbar default.navbar nav.current menu.

Automation & Industrial Robotic Integration Indo Sateki Solution Also called rectilinear and gantry robots and named after a famous mathematician. The robot industry has defined classifications for the most common and these are: This article presents the different classifications with some examples. Apart from gas and arc welding, polar robots are also used in. Its arm is in cylindrical in design.

Industrial robots What are the different types? (i) cartesian configuration, (ii) cylindrical configuration, (iii) polar configuration, and. A simpler, more complete definition of robotic types can be narrowed down to five types: Robots are used to drive efficiency, expedite processes, improve safety, and enhance experiences across many industries. • linear robots (including cartesian and gantry robots) • scara robots • articulated robots • parallel robots (delta) •.

Small Industrial Robots What Are The Different Types? Techicy With rotary joints and six degrees of freedom, they offer superior directional control and can. That’s why in my opinion one of the best ways how to divide robots into types is a division by their application. • linear robots (including cartesian and gantry robots) • scara robots • articulated robots • parallel robots (delta) • cylindrical robots •. As.

Small Industrial Robots What Are The Different Types? Techicy There are several basic types of industrial robots commonly used: This means that they are able to carry out a wider variety of tasks than robots that feature fewer axes. The links in the arm are connected by rotary joints. Nowadays, robots do a lot of different tasks in many fields and the number of jobs entrusted to robots is.

Types of Industrial Robots These robots have three linear joints that use the cartesian coordinate system (x, y, z). There are several basic types of industrial robots commonly used: • articulated • scara • cartesian • parallel (or delta) • cylindrical. However, for operations where more flexibility is required, a more suitable choice would be an articulated robot. Scara robots specialize in lateral movements.

On the basis of physical configuration industrial robots are classified in four different types. Types of Industrial Robots.

This means that they are able to carry out a wider variety of tasks than robots that feature fewer axes. The arm is connected to the base with a twisting joint. Intel offers the computing hardware, ai technologies, and vision. Each of these types offers a different joint configuration. Polar or spherical robot arm. A simpler, more complete definition of robotic types can be narrowed down to five types:

Cartesian robots are also called rectilinear or gantry robots and have a rectangular configuration. Then there is also a new qualifier for industrial robots that can be collaborative or not. Industrial robots provide a variety of benefits: Types of Industrial Robots, The robot industry has defined classifications for the most common and these are: