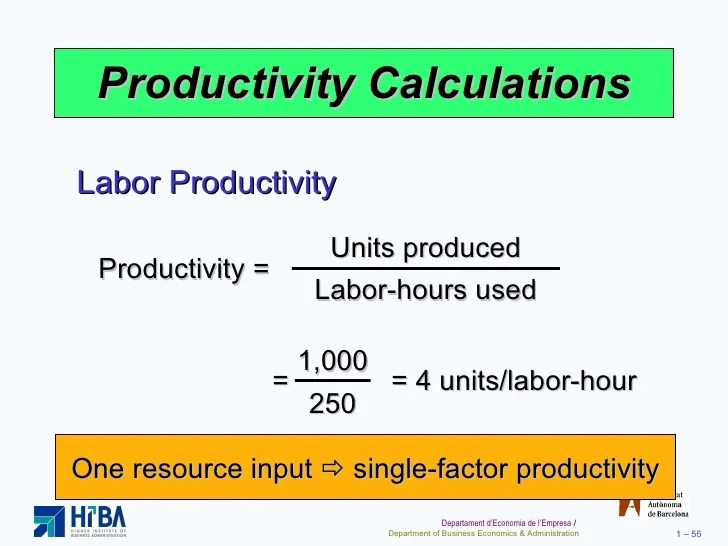

The calculation method for the labor productivity ratio is simply the amount of output divided by the amount of input. It also indicates extensive use of technology, automation and capital.

Labor Productivity Formula Operations Management, Its significance lies in its focus on utilization of one resource. For an average employee on a factory floor, the output can.

The 3 types of productivity are total productivity, partial productivity, and factor productivity available in operations management. In our example, let’s use three employees. Let’s say your business generated $ 80,000 worth of. How to calculate the productivity ratio formula.

Capacity Utilisation Business tutor2u In our example, let’s use three employees. This means employee productivity per week is. We will also need the previously introduced definitions of flow. You can measure employee productivity with the labor productivity equation: Decide what number represents the output.

Introduction To Operation Management The production is done to fulfill the consumer requirement. Usually productivity is expressed as a rate of something (time, unit, etc) and efficiency as a percentage based on a standard. Total output / total input. The productivity for your best guy is still 25 per hour, but his efficiency compared to the standard is 25 divided by 30 is 83.33%..

Ent300 Module09 The production is done to fulfill the consumer requirement. The productivity for your best guy is still 25 per hour, but his efficiency compared to the standard is 25 divided by 30 is 83.33%. Ways to improve productivity 1.product development 2.specialisation and standardisation 3.market, consumer and product research 4.value analysis 5.process planning and research 6.method study 7.safety 8.operator training 9.production.

PPT Production and Operation Management PowerPoint Presentation, free It is expressed in mks unit or cgs unit or in numbers. Your most productive worker, may not be really efficient based on standard time. Start studying operations management chapter 1 (productivity calculations). A large number of techniques have been developed for improving productivity. The calculation will be the amount spent to generate goods or services divided by the number.

Productiivity vs production Your most productive worker, may not be really efficient based on standard time. The more productive a company is, the better it uses its resources. Capacity, bottleneck, process capacity, flow rate and utilization. How to calculate the productivity ratio formula. How productivity can be increased.

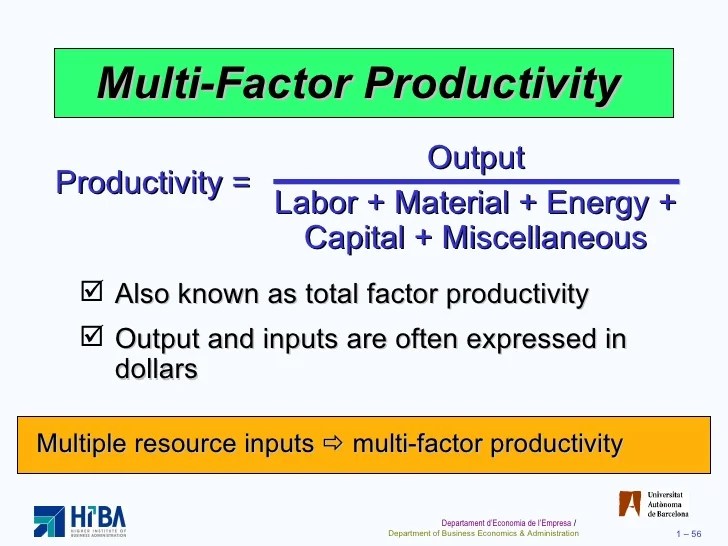

Long Run Aggregate Supply Economics tutor2u If one does not focus on a specific form of. Outputs/ inputs partial measures include outputs/labour, output/capital, etc. Transaction / on crew hours = tpmh ( transaction per man hour ) tpmh will give you the right productivity measuring numbers. Where, tfp = total factor productivity. Recall that operations management is responsible for managing the transformation of numerous inputs into.

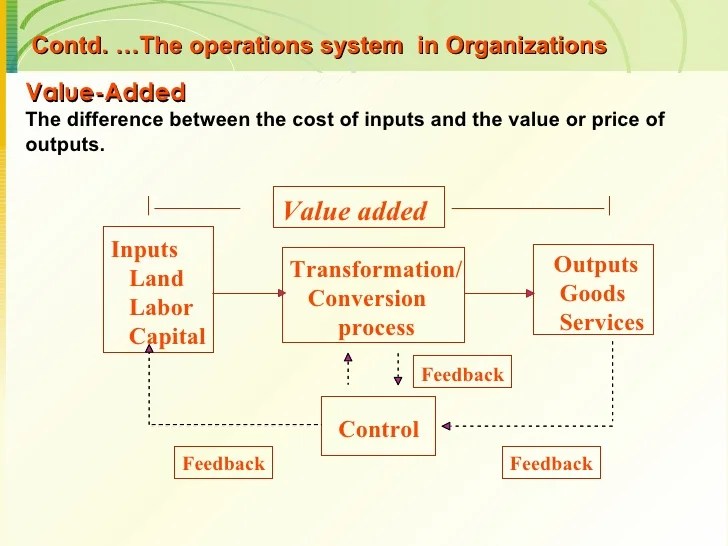

Production and Operations Management Chapters 18 Recall that operations management is responsible for managing the transformation of numerous inputs into a range of outputs, such as goods or services. It also indicates extensive use of technology, automation and capital. To inputs (labor and materials). Output / labor + material + energy + capital + miscellaneous. Each freight container can have from 40 cases to 20,000 cases.

62 FORMULA FOR MULTIFACTOR PRODUCTIVITY, MULTIFACTOR PRODUCTIVITY Usually productivity is expressed as a rate of something (time, unit, etc) and efficiency as a percentage based on a standard. Start studying operations management chapter 1 (productivity calculations). Its current operations and management practices should be examined to decide how they should function in the future. You can measure employee productivity with the labor productivity equation: The 3 types.

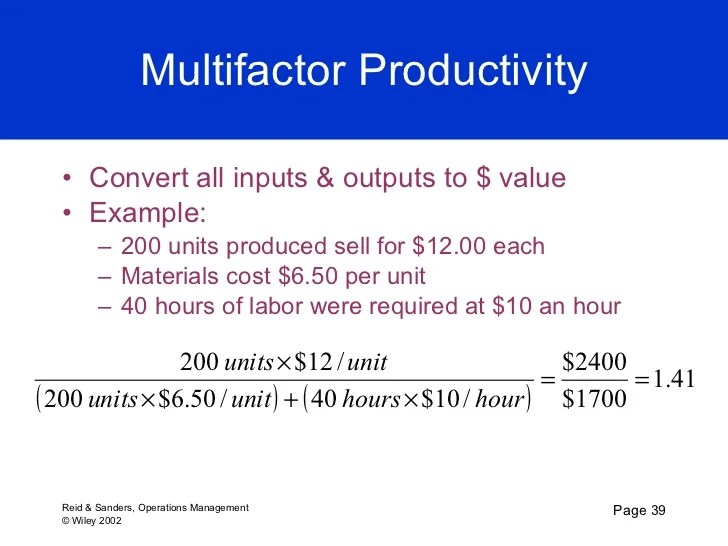

Labour Productivity Business tutor2u You can measure employee productivity with the labor productivity equation: In this video i demonstrate how to calculate productivity measures for a company, how to automate calculations using a simple macro, and finally how to use p. Total productivity = total output / total input = $12,000 / $6,000 = 2.0. It is expressed in mks unit or cgs unit.

Production Management with Examples StudiousGuy For an average employee on a factory floor, the output can. The labor productivity might, for example, be four output units (such as car or netbook parts) per labor hour. If a manufacturing facility is able to produce $12,000 worth of product using inputs such as machinery, and labor costs that equal $6,000, the productivity output would equal two. A.

Operations Management Productivity Measurements YouTube The result is a dollar amount of productivity per employee. If a manufacturing facility is able to produce $12,000 worth of product using inputs such as machinery, and labor costs that equal $6,000, the productivity output would equal two. Identify the productivity ratio formula. In our example, let’s use three employees. Its significance lies in its focus on utilization of.

Multifactor Productivity YouTube For an average employee on a factory floor, the output can. Your most productive worker, may not be really efficient based on standard time. Labour productivity is used to measure efficiency. The result is a dollar amount of productivity per employee. If one does not focus on a specific form of.

Productivity in Dentistry The book entitled production and operations management is designed to. This measure of productivity can. You can measure employee productivity with the labor productivity equation: A popular method for measuring productivity in a factory setting is to compare total labor time, which is also called the input, with the number of products manufactured, or the output. Total output / total.

Production and Operations Management Chapters 18 The equation is as follows: The productivity formula is simple: Your most productive worker, may not be really efficient based on standard time. If one does not focus on a specific form of. This measure of productivity can.

Production rate It also indicates extensive use of technology, automation and capital. It can be expressed as: How to calculate the productivity ratio formula. Labour productivity is used to measure efficiency. To measure productivity in this way, you will divide.

Economies of Scale and Resource Mix In order to perform the following calculations, processing time has to be defined as the time that is spent on a certain task (e.g. Decide what number represents the output. Total factor productivity has the benefit of easy calculation and more useful form economic view points. You can measure employee productivity with the labor productivity equation: Let’s say your business.

PPT OPERATION MANAGEMENT OPERATIONS AND PRODUCTIVITY PowerPoint It is the conversion of inputs to desired output. This means employee productivity per week is. Recall that operations management is responsible for managing the transformation of numerous inputs into a range of outputs, such as goods or services. Production is the creation of goods and services operations management (om) is the set of activities that creates value in the.

⚡ Definition operations management function. Functions of production To inputs (labor and materials). For an average employee on a factory floor, the output can. If one does not focus on a specific form of. How to calculate the productivity ratio formula. Capacity, bottleneck, process capacity, flow rate and utilization.

Production and Operations Management Chapters 18 You can measure employee productivity with the labor productivity equation: Usually productivity is expressed as a rate of something (time, unit, etc) and efficiency as a percentage based on a standard. Total factor productivity has the benefit of easy calculation and more useful form economic view points. The 3 types of productivity are total productivity, partial productivity, and factor productivity.

PPT Operations Management Competing with Operations Chapter 1 Decide what number represents the output. If one does not focus on a specific form of. Learn vocabulary, terms, and more with flashcards, games, and other study tools. Output is something that a company or part of a company generates. The formula is output / input = productivity.

Calculating Productivity for Employees, Software & More The book entitled production and operations management is designed to. In our example, let’s use three employees. The equation is as follows: The productivity for your best guy is still 25 per hour, but his efficiency compared to the standard is 25 divided by 30 is 83.33%. We will also need the previously introduced definitions of flow.

Operations And Productivity Learn vocabulary, terms, and more with flashcards, games, and other study tools. To inputs (labor and materials). In our example, let’s use three employees. The productivity formula is simple: Labour productivity is used to measure efficiency.

12 Useful Formulas for Industrial Engineers (Poster) Online Clothing To inputs (labor and materials). If one does not focus on a specific form of. Outputs/ inputs partial measures include outputs/labour, output/capital, etc. In this video i demonstrate how to calculate productivity measures for a company, how to automate calculations using a simple macro, and finally how to use p. We will also need the previously introduced definitions of flow.

Operations And Productivity The productivity formula is simple: Usually productivity is expressed as a rate of something (time, unit, etc) and efficiency as a percentage based on a standard. Total factor productivity (tfp) =output /input (labor+capital). Your most productive worker, may not be really efficient based on standard time. If a manufacturing facility is able to produce $12,000 worth of product using inputs.

Productivity Benchmarks How to Calculate the Labor Productivity The result is a dollar amount of productivity per employee. Labour productivity is used to measure efficiency. Identify the productivity ratio formula. A large number of techniques have been developed for improving productivity. (x^n), where x= number of units, y= number of direct labor hours required to produce the xth unit, k= number of direct labor hours required to.

The more productive a company is, the better it uses its resources. Productivity Benchmarks How to Calculate the Labor Productivity.

The labor productivity might, for example, be four output units (such as car or netbook parts) per labor hour. The productivity for your best guy is still 25 per hour, but his efficiency compared to the standard is 25 divided by 30 is 83.33%. The calculation will be the amount spent to generate goods or services divided by the number of employees. This means employee productivity per week is. Its current operations and management practices should be examined to decide how they should function in the future. Capacity, bottleneck, process capacity, flow rate and utilization.

The calculation will be the amount spent to generate goods or services divided by the number of employees. However, to manage operations daily per employee, it is not effective. How productivity can be increased. Productivity Benchmarks How to Calculate the Labor Productivity, To calculate labor productivity, divide the total value of the goods and services produced by the total number of hours worked.