That way, the company can grow, the team can know exactly what to focus on, and the results such as increased. There are a number of common standards for measuring manufacturing performance.

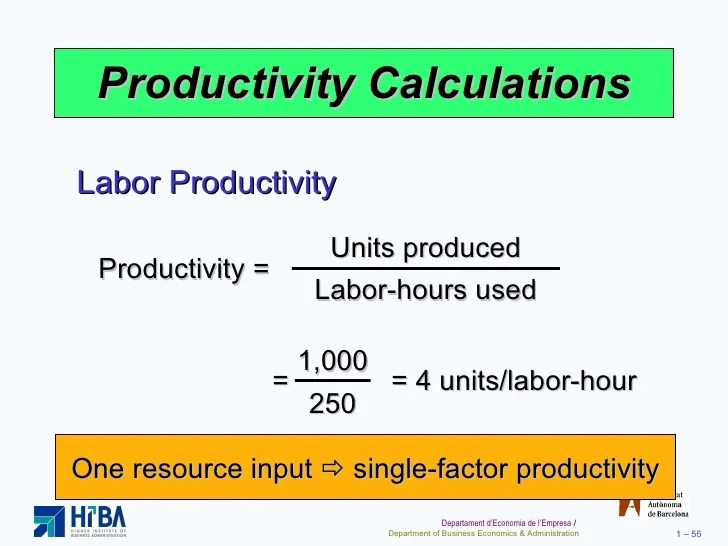

How To Measure Productivity In Operations Management, Total output / total input. Transformation efficiency = output / capacity;

Productivity metrics are used to track and measure how efficient your team is in getting their tasks done. Performance here is defined as the degree to which an operation fulfils the five performance objectives at any point in time, in order to satisfy its customers. Part of managing processes is to measure their performance. How about in labor productivity in dollars?

PPT Operations Management PowerPoint Presentation, free download ID To increase productivity, the ratio of outputs to inputs is made as large as practical. Productivity = output / input; For instance, simply, productivity is measured like this: What is the labor productivity in hours for each car type? A factory cannot perform well on every yardstick.

Work study production and operations management Employees right from the stage where you define the metrics [for] productivity, he said. The model can be applied to any manufacturing organization or service company. Productivity is defined as a total output per one unit of a total input. So the job of productivity measurement is to highlight how to get more units of output (goods produced. Labor productivity.

Labour Productivity Business tutor2u Example • in case a, 10 products are produced spending 1000 rupees and in case b, 15 products are produced by spending 2000 rupees. To calculate your company’s labor productivity, you would divide 80,000 by 1,500, which equals 53. A polar diagram can be used to see. Beyond the usual traits of great leaders, your ops manager will need a.

Operations And Productivity Transformation efficiency = output / capacity; This measure of productivity can be used to measure the productivity of one worker or many, as well as the productivity of a machine, a department, the whole firm, or even a nation. This article will discuss 2 basic process measures: So how do you measure productivity? Productivity = outputs / inputs.

Operations strategy and competitiveness online presentation Crisis management and business continuity planning. Part of managing processes is to measure their performance. Intangible output of service sector: Total productivity = total output / total input Divide the output by the input.

Work study production and operations management The activity of measuring and assessing the various aspects of a process or whole operation’s performance. This measure of productivity can be used to measure the productivity of one worker or many, as well as the productivity of a machine, a department, the whole firm, or even a nation. Identify potential risks, prepare for emergencies and test your business� disaster.

Why Operational Efficiency Is Your New Marketing Metric Measuring Measuring productivity can help you determine if you’re on track to meet your goals. Total factor productivity has the benefit of easy calculation and more useful form economic view points. That is my target audience. Productivity = output / input; Among these are short delivery cycles, superior product quality and reliability, dependable delivery promises, ability to produce new products quickly,.

A Framework for Improving Operational Efficiency in Investment Banks Productivity = output / input; Transformation efficiency = output / capacity; Employees� overall productivity can include how effectively they manage their time to complete projects and tasks. How about in labor productivity in dollars? To increase productivity, the ratio of outputs to inputs is made as large as practical.

The Survival Guide to Operational Performance Excellence Visual.ly There are two ways to measure this. Employees� overall productivity can include how effectively they manage their time to complete projects and tasks. So how do you measure productivity? To demonstrate the approach, let’s take one of the questions from the business unit managers list and walk through the necessary steps: Employees right from the stage where you define the.

Efficiency vs. Productivity Metrics that Matter…Until They Don’t Beyond the usual traits of great leaders, your ops manager will need a solid grasp of: The productivity is a measure of how much input is required to achieve a given output. Identify the risks your business may face and learn to set up an effective risk management program to maximize your chances of success. The operations team is in.

Capacity utilisation tutor2u Business Total factor productivity has the benefit of easy calculation and more useful form economic view points. Labor productivity = output / labor time; You can measure employee productivity with the labor productivity equation: Additionally, determine which metrics and reports measure efficiency, identify improvements, or show results. Identify the risks your business may face and learn to set up an effective.

Operations Management Archive February 01, 2016 The operations team is in place to ensure the company is running at peak efficiency. Total output / total input. Measuring productivity can help you determine if you’re on track to meet your goals. Constraints in measuring productivity are discussed below: Protect your business from theft.

Operations management All this creates difficulties in measuring productivity. This video series is for those new to operations management or individuals who just want to know a little more about om basics. Employees� overall productivity can include how effectively they manage their time to complete projects and tasks. Divide the output by the input. How about in labor productivity in dollars?

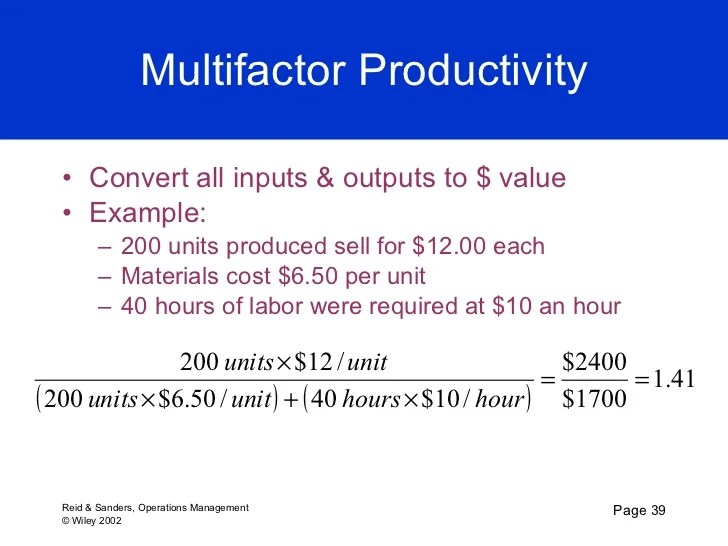

Calculating Productivity for Employees, Software & More Total productivity =total tangible output +total trangible input. However, productivity metrics differ from other metrics like quality metrics, which often use numbers and percentages to show a result. Performance here is defined as the degree to which an operation fulfils the five performance objectives at any point in time, in order to satisfy its customers. Multifactor productivity = output (in.

PPT EFFICIENCY MEASUREMENT OF LIFELONG LEARNING PowerPoint That is my target audience. Total productivity =total tangible output +total trangible input. For example, let’s say a company produces. That way, the company can grow, the team can know exactly what to focus on, and the results such as increased. Employees� overall productivity can include how effectively they manage their time to complete projects and tasks.

Measure Your Manufacturing KPIs Force Intellect Beyond the usual traits of great leaders, your ops manager will need a solid grasp of: Total productivity is used when measuring productivity for all inputs combined, such as labor, machines, and capital. The productivity is a measure of how much input is required to achieve a given output. Total output / total input. Various processes across the company, so.

Productiivity vs production Part of managing processes is to measure their performance. Of course, this requires having a clear understanding of what your goals are. So the job of productivity measurement is to highlight how to get more units of output (goods produced. The model can be applied to any manufacturing organization or service company. Rather, productivity is output divided by input.

Efficiency Ratios Formulas & Interpretation. Example with Calculation Total tangible output = value of finished goods produced + value of partialunits produced + dividents from securities + interest+ other income Productivity is defined as a total output per one unit of a total input. You can measure employee productivity with the labor productivity equation: The model can be applied to any manufacturing organization or service company. Of course,.

Productivity Operations Management Simulation YouTube What is the labor productivity in hours for each car type? Productivity metrics are used to track and measure how efficient your team is in getting their tasks done. Productivity challenge productivity is the ratio of outputs (goods and services) divided by the inputs (resources such as labor and capital) the objective is to improve productivity! Changing price of inputs.

Operational KPIs 33 Productivity KPI Examples to Measure This video series is for those new to operations management or individuals who just want to know a little more about om basics. Productivity measures in operations management. Total productivity measure (tpm) it is based on all the inputs. To calculate your company’s labor productivity, you would divide 80,000 by 1,500, which equals 53. A measure of how efficiently an.

Operations And Productivity The activity of measuring and assessing the various aspects of a process or whole operation’s performance. To increase productivity, the ratio of outputs to inputs is made as large as practical. This video series is for those new to operations management or individuals who just want to know a little more about om basics. Protect your business from theft. Part.

PPT Chapter 2 Operations Strategy and Competitiveness PowerPoint Let’s say your company generated $80,000 worth of goods or services (output) utilizing 1,500 labor hours (input). For instance, simply, productivity is measured like this: Total output / total input. Knowing what matters to your company will ensure you avoid measuring aspects of productivity that have little relevance to your business. Employee involvement and support from leadership should be a.

Efficiency Formula Calculate Operator Efficiency and Line Efficiency Divide the output by the input. Total productivity =total tangible output +total trangible input. A polar diagram can be used to see. To calculate your company’s labor productivity, you would divide 80,000 by 1,500, which equals 53. A factory cannot perform well on every yardstick.

PPT OPERATION MANAGEMENT OPERATIONS AND PRODUCTIVITY PowerPoint For example, let’s say a company produces. A measure of how efficiently an organization converts inputs into outputs. So how do you measure productivity? Employee involvement and support from leadership should be a priority for all managers when tracking their workers� productivity, said boydas. Beyond the usual traits of great leaders, your ops manager will need a solid grasp of:

62 FORMULA FOR MULTIFACTOR PRODUCTIVITY, MULTIFACTOR PRODUCTIVITY What metrics do you use? Intangible output of service sector: This article will discuss 2 basic process measures: What is the labor productivity in hours for each car type? Control management must implement control processes to maintain or improve productivity.

There are a number of common standards for measuring manufacturing performance. 62 FORMULA FOR MULTIFACTOR PRODUCTIVITY, MULTIFACTOR PRODUCTIVITY.

Crisis management and business continuity planning. Total factor productivity has the benefit of easy calculation and more useful form economic view points. Beyond the usual traits of great leaders, your ops manager will need a solid grasp of: For example, let’s say a company produces. Total productivity is used when measuring productivity for all inputs combined, such as labor, machines, and capital. Crisis management and business continuity planning.

For instance, simply, productivity is measured like this: Total productivity = total output / total input There are two ways to measure this. 62 FORMULA FOR MULTIFACTOR PRODUCTIVITY, MULTIFACTOR PRODUCTIVITY, Control management must implement control processes to maintain or improve productivity.