It is calculated by dividing the outputs produced by a company by. Productivity can be calculated as the ratio of the volume of output to the volume of inputs.

Calculating Productivity In Operations Management, You will see many of the components of tqm in other quality management approaches. Production target per hour (@100 efficiency) = (60/operation sam)

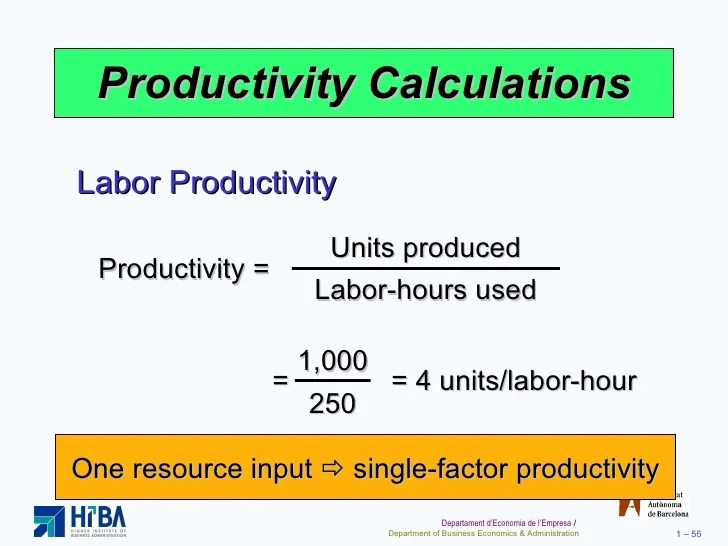

Productivity = output / input in this problem, the following are the multifactor productivity of dulac box plant before and after that are given as: This measure of productivity can be used to measure the productivity of one worker or many, as well as the productivity of a machine, a department, the whole firm, or even a nation. We will also need the previously introduced definitions of flow. These factor affecting productivity in operation management can be divided into.

Throughput Time, Manufacturing Cycle Efficiency A factory cannot perform well on every yardstick. The production target is calculated from the garment sam. I hope that helps u out. The labor productivity might, for example, be four output units (such as car or netbook parts) per labor hour. The operations team is in place to ensure the company is running at peak efficiency.

Capacity Equation Operations Management Tessshebaylo This can be better than measuring profit against time as the goal is to get your team to work smarter, not longer. There are a number of common standards for measuring manufacturing performance. For the next period, the output is doubled (320 kg) by consuming 420 kg of raw material and for a third period, the output is increased to.

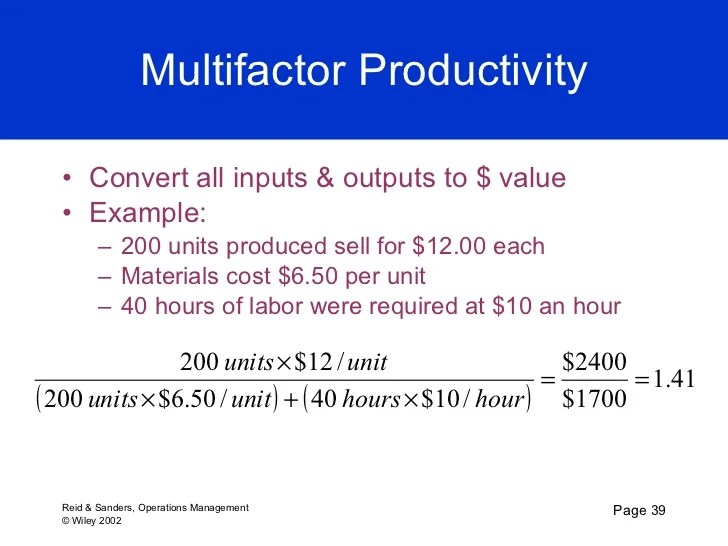

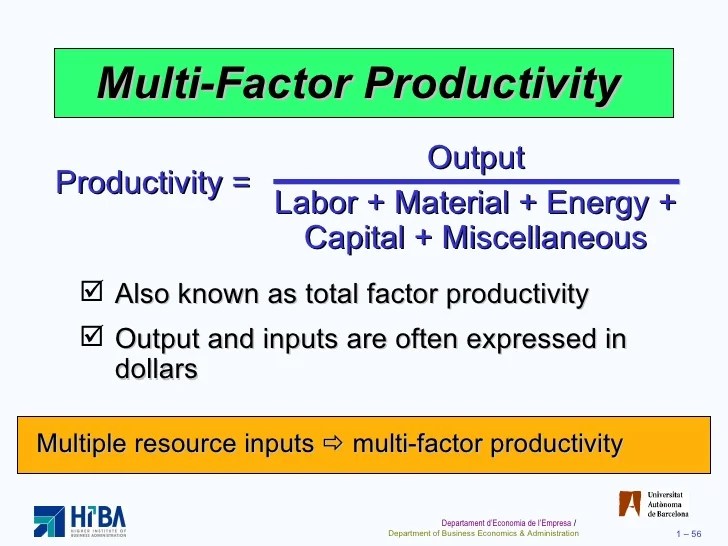

Independent demand inventory management презентация онлайн It is vital to have a high productivity rate because resources like capital and time are scarce and should be exploited in the best possible way. Utilization=worked hrs/available hrs, efficiency =standard paid hrs/worked hrs, and productivity =utilization*efficiency. Multifactor productivity whereas the partial factor productivity formula uses one single input, the multifactor. External factor are those factors, which are beyond the.

PPT Chapter 2 Operations Strategy and Competitiveness We will also need the previously introduced definitions of flow. Rather, productivity is output divided by input. The productivity is a ratio between the output and input that is calculated on the basis of following formula: There are a number of common standards for measuring manufacturing performance. This becomes important when calculating operational efficiency, as the two must be added.

62 FORMULA FOR MULTIFACTOR PRODUCTIVITY, MULTIFACTOR The operations team is in place to ensure the company is running at peak efficiency. This can be better than measuring profit against time as the goal is to get your team to work smarter, not longer. This approach is important because of the focus on a continuous cycle of improving. The “getting shit done” strategy What metrics do you.

What is Utilization + How do You Calculate Utilization Rate? Capacity, bottleneck, process capacity, flow rate and utilization. Regularly calculating productivity allows an organization and its employees the opportunity to track and analyze elements of its operation. The more productive a company is, the better it uses its resources. Productivity is computed as a ratio of total output divided by total input using the following equation: If one does not.

IGCSE Mathematics How to calculate percentage increase For the next period, the output is doubled (320 kg) by consuming 420 kg of raw material and for a third period, the output is increased to 400 kg by consuming 400 kg of raw material. Productivity is expressed and measured in monetary units per input as this seems to be the only practical way (stainer, 1997). So the job.

62 FORMULA FOR MULTIFACTOR PRODUCTIVITY, MULTIFACTOR Productivity can be calculated as the ratio of the volume of output to the volume of inputs. So how do you measure productivity? The “getting shit done” strategy Total productivity • the method of calculating productivity considering all the resources is called total productivity. There are a number of common standards for measuring manufacturing performance.

Solved Calculate The Productivity Growth You Would Use To Productivity is computed as a ratio of total output divided by total input using the following equation: In the second formula, instead of calculating minutes, we are considering produced garments as output and production targets for the given hours as an input. The “getting shit done” strategy This becomes important when calculating operational efficiency, as the two must be added.

Operations And Productivity This becomes important when calculating operational efficiency, as the two must be added together. This can be better than measuring profit against time as the goal is to get your team to work smarter, not longer. Productivity measures the efficiency of a company�s production process. One station in a sandwich restaurant). In the second formula, instead of calculating minutes, we.

Production Operations Management Fundamentals of Inventory Production target per hour (@100 efficiency) = (60/operation sam) So how do you measure productivity? About press copyright contact us creators advertise developers terms privacy policy & safety how youtube works test new features press copyright contact us creators. Productivity is affected by various factors. The production target is calculated from the garment sam.

Operations And Productivity Tqm is one of the bedrock approaches to quality management. For the next period, the output is doubled (320 kg) by consuming 420 kg of raw material and for a third period, the output is increased to 400 kg by consuming 400 kg of raw material. • total productivity provides a systematic framework and structure to an organization and increase.

Operations management Productivity is expressed and measured in monetary units per input as this seems to be the only practical way (stainer, 1997). These factor affecting productivity in operation management can be divided into. The equation is as follows: Productivity is a measure of the efficiency of a machine, factory or person in converting inputs into useful outputs. Capacity, bottleneck, process capacity,.

Absenteeism Rate How to Calculate & Use Absence Rate in • total productivity provides a systematic framework and structure to an organization and increase profitability. Various problems have been identified with productivity measurements that have led to doubts about the reliability and validity of measuring productivity at the macro level (rojas & aramvareekul, 2003). Productivity is expressed and measured in monetary units per input as this seems to be the.

Efficiency Formula Calculate Operator Efficiency and Line The productivity is a ratio between the output and input that is calculated on the basis of following formula: Productivity is affected by various factors. Total productivity = total output / total input Productivity can be calculated as the ratio of the volume of output to the volume of inputs. One station in a sandwich restaurant).

Productiivity vs production You can use this multifactor productivity calculator, by providing the number of units produced, and the dollar value of all inputs used, specifying the name of the resource used (use only the boxes that you need, leave empty the ones that you don�t use): Production target per hour (@100 efficiency) = (60/operation sam) Total productivity • the method of calculating.

Production rate Productivity measures the efficiency of a company�s production process. This analysis can lead to improvements in efficiency, time management and overall revenue. It is calculated by dividing the outputs produced by a company by. In this video i demonstrate how to calculate productivity measures for a company, how to automate calculations using a simple macro, and finally how to use.

Capacity Utilisation Business tutor2u The labor productivity might, for example, be four output units (such as car or netbook parts) per labor hour. So how do you measure productivity? It is vital to have a high productivity rate because resources like capital and time are scarce and should be exploited in the best possible way. A factory cannot perform well on every yardstick. Productivity.

Operations And Productivity Rather, productivity is output divided by input. For the next period, the output is doubled (320 kg) by consuming 420 kg of raw material and for a third period, the output is increased to 400 kg by consuming 400 kg of raw material. The productivity is a ratio between the output and input that is calculated on the basis of.

PPT Chapter 2 Operations Strategy and Competitiveness A factory cannot perform well on every yardstick. If one does not focus on a specific form of. Productivity measures in operations management. You can use this multifactor productivity calculator, by providing the number of units produced, and the dollar value of all inputs used, specifying the name of the resource used (use only the boxes that you need, leave.

Capacity Utilisation tutor2u Business The operations team is in place to ensure the company is running at peak efficiency. This can be better than measuring profit against time as the goal is to get your team to work smarter, not longer. The “getting shit done” strategy It is calculated by dividing the outputs produced by a company by. • it is systematic and qualitative.

PPT HL OPERATIONS MANAGEMENT PRODUCTION PLANNING Productivity is computed as a ratio of total output divided by total input using the following equation: Productivity is affected by various factors. The below formula is used for calculating the production target. If one does not focus on a specific form of. Productivity = output / input in this problem, the following are the multifactor productivity of dulac box.

Operations And Productivity It is vital to have a high productivity rate because resources like capital and time are scarce and should be exploited in the best possible way. Multifactor productivity whereas the partial factor productivity formula uses one single input, the multifactor. The productivity is a ratio between the output and input that is calculated on the basis of following formula: Tqm.

PPT Production and Operation Management PowerPoint Productivity is a measure of the efficiency of a machine, factory or person in converting inputs into useful outputs. In this video i demonstrate how to calculate productivity measures for a company, how to automate calculations using a simple macro, and finally how to use p. The “getting shit done” strategy Regularly calculating productivity allows an organization and its employees.

How to Calculate Workplace Productivity Smartsheet Productivity is affected by various factors. For the next period, the output is doubled (320 kg) by consuming 420 kg of raw material and for a third period, the output is increased to 400 kg by consuming 400 kg of raw material. You will see many of the components of tqm in other quality management approaches. You can use this.

This page explores the nature of total quality management (tqm) and the necessity of use in the operations environment. How to Calculate Workplace Productivity Smartsheet.

The formula used for calculating the operational efficiency ratio/operating ratio is as follows: Productivity = output / input in this problem, the following are the multifactor productivity of dulac box plant before and after that are given as: During the first year, production is 160 kg. • total productivity provides a systematic framework and structure to an organization and increase profitability. These factor affecting productivity in operation management can be divided into. This page explores the nature of total quality management (tqm) and the necessity of use in the operations environment.

Capacity, bottleneck, process capacity, flow rate and utilization. These factor affecting productivity in operation management can be divided into. This measure of productivity can be used to measure the productivity of one worker or many, as well as the productivity of a machine, a department, the whole firm, or even a nation. How to Calculate Workplace Productivity Smartsheet, Productivity is expressed and measured in monetary units per input as this seems to be the only practical way (stainer, 1997).